The corrosion and other problems associated with salt water circulation systems can be minimized by using it for cooling central coolers through which fresh water from a closed general cooling circuit is passed. Central cooling system & Scoop arrangement for motorships.Indcation that fouling has occured is given by a progressive increase in the temperature difference between the two fluids, and change of pressure. The only attention that marine heat exchangers should require is to ensure that the heat transfer surfaces should remain substantially clean and flow passage generally clear of obstructions. The charge air coolers fitted to reduce the temperature of air after the turbo-charger and before entry to the diesel engine cylinder, are provided with fins on the heat transfer surfaces to compensate for the relatively poor heat transfer properties of air. The major advantage over tube type coolers, is that their higher efficiency is reflected in a smaller size for the same cooling capacity. The obvious feature of plate type heat exchangers, is that they are easily opened for cleaning. The sea water is in contact with the inside of the tubes, tube plates and water boxes.

Shell and tube heat exchangers for engine cooling water and lubricating oil cooling have traditionally been circulated with sea water.

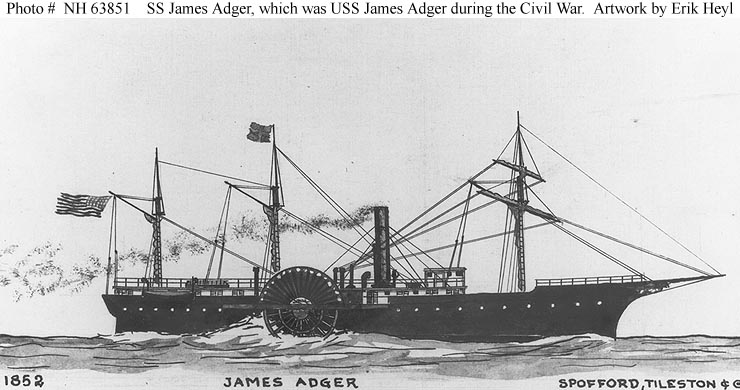

STEAM SHIPS PLUS

The usual arrangement for motorships has been to have sea-water circulation of coolers for lubricating oil, piston cooling, jacket water, charge air, turbo-charger oil (if there are sleeve type bearings) and fuel valve cooling, plus direct sea-water cooling for air compressors and evaporators. Summarized below various circulating systems for motorships, some of the basic procedure of heat exchangers & control of temperatures: The axial flow pump, intended for slow speed and manoeuvring, suffered from thrust problems when idling in a number of installations. Small axial flow circulating pumps (Figure 2) have been installed in conjunction with some scoop arrangements, with the idea that at speed, the pump impeller would idle and provide very little resistance to the scoop flow. Scoops have been preferred for fast, high-powered steamships, with circulation only through a single large condenser and sufficient speed to ensure that the scoop gives an adequate flow of water.įig 1:Conventional sea-water circulation system Alternatively, the arrangement may be based on a scoop to supply the mainĬondenser. The main sea-water inlets, port and starboard, may be arranged as for the motorship example (Figure 1) with high and low suctions, orthodox double entry circulating pump (with emergency bilge suction) and a stand-by pump. The difference is that the sea water passes through a large condenser and an oil cooler rather than central coolers and then to the overboard discharge. The main sea-water circulating system for a ship with main propulsion by steam turbine is similar to that of a motorship with a central cooling system.

STEAM SHIPS HOW TO

COVID-19 Portal While this global health crisis continues to evolve, it can be useful to look to past pandemics to better understand how to respond today.Student Portal Britannica is the ultimate student resource for key school subjects like history, government, literature, and more.Demystified Videos In Demystified, Britannica has all the answers to your burning questions.This Time in History In these videos, find out what happened this month (or any month!) in history.#WTFact Videos In #WTFact Britannica shares some of the most bizarre facts we can find.Britannica Classics Check out these retro videos from Encyclopedia Britannica’s archives.Britannica Explains In these videos, Britannica explains a variety of topics and answers frequently asked questions.

0 kommentar(er)

0 kommentar(er)